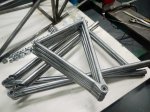

The upper control arms are all identical except that the bearing cups are mirrored from the left to the right so that the snap rings are on the bottom. If I can find a way to stake the spherical bearings then all four could be identical. Staking is a process that uses a hydraulic press to deform the bearing cup into a chamfer around the circumference of the spherical bearing, holding it permanently in place.

I printed out the layout of both control arms onto size A0 paper, glued the paper to a sheet of plywood, and drilled holes for the centerlines of each rod end and spherical bearing. This gives me a jig I can use for tack welding the parts in place. Washers under the bearing cups locate them vertically for tacking. The bearing cups proved a little too thin to weld without distortion, so I had to re-cut the spherical bearing bores after welding. Luckily I have an indexable end mill of just the right diameter, and running my mill at high speed with a lot of coolant gave a good finish on the bores. I then pressed the spherical bearings into place before painting as I wanted to make sure there were no glitches that would require messing up the paint to fix.

I sprayed Jotun Penguard 2-part epoxy paint directly onto the steel after first making sure the steel was scrupulously clean with a Scotchbrite pad on an angle grinder, followed by a cleaning with acetone and paper towels. The finish came out beautifully.

- Upper A-arm first leg

- Upper A-arm second leg

- Upper A-arm anti-intrusion bar

- Re-cutting the spherical bearing bores

- Finished set of 8 A-arms

- Finished set of eight pushrods & tierods

- Ready for paint

- Gloss black

- Finished set of control arms, tierods & pushrods

Hi, what is A arms diameter and thickness you are using? And what are your suggestions for a CNO2 type (2 liter sports racer) I am trying build just to have an idea.

Congratulations for your project!

Thank you

PK

Lower A-arms are 1″ diameter, 0.062″ thick. Upper A-arms are 3/4″ diameter, 0.050″ thick. The required strength of these components depends heavily on the geometry of the suspension, so you have to do your own calculations. There’s not really and easy way around that.