Chassis Jig Table

As I plan on building many of these cars, and they must all be exactly identical, I have to start with an absolutely flat, true, square, level, solid and repeatable surface. To that end I designed this chassis jig table out of 3″ and 4″ x 1/4″ steel C-channel. Over 500 pounds of it. I initially started the gardener off cutting steel, and although I told him it had to be perfect, 45 degrees seems to mean anywhere between 43 and 47 degrees to him so that didn’t work.

Next I hired my long-time Honda repair & upgrade mechanic to work for me full time, but he mysteriously stopped showing up for work and his phone stopped working after a week or two so I ended up building the table myself.

Anyway, now I know the table is as perfect as hand tools and my milling machine can make it. I figure it’s plus or minus less than half a millimeter over its length of 3.3 meters. The table sits on eight 5/8″ bolts that serve as adjustable feet, and in adjusting the table I found out just how out of level the concrete floor of the operating room is. I figure if I really want to make it perfect, I can flood the pit you see in the photos so the surface of the water is exactly level with the surface of the table, but that might be excessive.

Painting the chassis jig table

This was also a good chance to practice my welding. The Thais think TIG welding is exclusively for stainless steel so I didn’t even bring up the idea of TIG welding 1/4″ steel channels, for which they would use plain old arc welding. I bought a fancy 200-amp all-adjustable TIG welder, the most high-end one I could find locally, but the sales staff said Thai people don’t use the pedal controls and so they are unavailable in Thailand, even though the plug for the pedal is clearly visible on the front of the unit. Unfortunately all the TIG welding videos and tutorials I can find on the web pretty much assume you have a pedal control. After I got chased out of another welding store for riffling through their plasma cutter tips, looking for one that fit my machine, I decided it might be easier to just look on Ebay US. What do you know, I found everything I need from a supplier in China. So I ordered from my computer in Thailand, on the US Ebay site, from a vendor in China, and paid with PayPal, and the supplies arrived before I expected them.There was a bit of a problem clearing customs as they didn’t believe the invoiced value on the box ($13, heh, heh), but DHL took care of everything and found my house without me giving them any directions. That’s a first.

TIG Welder Foot Control

And what a difference the pedal control makes! What was previously almost impossible becomes fairly easy. Now I think I’ll get some more practice by welding up some playground equipment for my daughters.

In case anybody needs it, here’s a free copy of the chassis jig drawings, four sheets of size A0 in PDF form. I just uploaded this file again as there was an error on the first page of the previously uploaded file, so anybody who downloaded the file before September 11, 2011 might want to get the latest version where you can see the top-level isometric view on the first page.

Also, note that there have been a couple of changes since this drawing was made. The holes for the feet are spec’d for 3/8″ bolts, but I upgraded them to 5/8″ (15.88mm).

Download Free! Chassis Jig Drawings

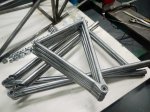

Then, while building the table, I found it was a little hard to adjust without some diagonal bracing to hold it in place while attaching the top crossmembers. I added the diagonal braces you can see in the photo, made of 1/2″ x 1/2″ x 0.062″ square tubing, pounded flat at the ends, drilled, and bolted to the tops of the leg assemblies with 1/4-20 bolts. This way I could adjust the table for squareness and it wouldn’t change when I tightened the top crossmember attachment bolts.