Finished front wing on the car (endplates to be added after setting ride height)

- Airfoil profile laser printed on sticker paper, stuck to aluminum sheet

- Airfoil profiles cut from aluminum sheet

- Homemade hot-wire foam cutter cutting airfoil section from styrofoam block

- Laminating outer skin of epoxy resin and fiberglass

- Cutting aluminum jacking points to be laminated into the wing

- Bending wing mounting brackets to be bolted to the nose

- Test fitting brackets on nose

- Test fitting, bottom view

- Trimming front wing airfoil on the bandsaw

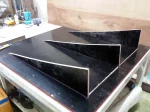

- Gluing 3 sections of front wing to brackets

- Reinforcing fiberglass skin across joints

- Laminating end plates with honeycomb core

- End plates cure under vacuum

- Sanding with pneumatic double-action sander

- Laying up endplate mounting points

- Epoxy & microballoon filler to smooth out the spar

- Top coat of 2-part epoxy paint

- Car lifted by front wing